MAPRO® International

Sejak tahun 1959, Mapro International S.p.A. telah memproduksi dan mengekspor mesin-mesin yang mengolah udara dan gas teknis ke seluruh dunia. Mapro International S.p.A. didirikan dengan nama perusahaan M.P.R. Italiana S.p.A., yang tujuannya adalah memproduksi kompresor baling-baling putar dan pompa vakum yang digunakan untuk penyedotan dan kompresi fluida gas, termasuk yang bersifat korosif.

Penggunaan mesin-mesin ini dalam berbagai sektor industri, mulai dari makanan hingga farmasi, dari mesin-mesin pembentuk hingga kemasan, dalam pabrik-pabrik proses, dalam pengendalian polusi lingkungan, dll., merupakan dasar dari pengalaman yang kokoh yang saat ini memungkinkan Perusahaan kami menyediakan solusi yang teknologis sesuai untuk digunakan dan dapat diandalkan dari waktu ke waktu untuk setiap proses transfer udara atau gas teknis.

PT Chemitra Abadi adalah distributor resmi Mapro blower di Indonesia. Kami juga melayani layanan purnajual untuk produk Mapro.

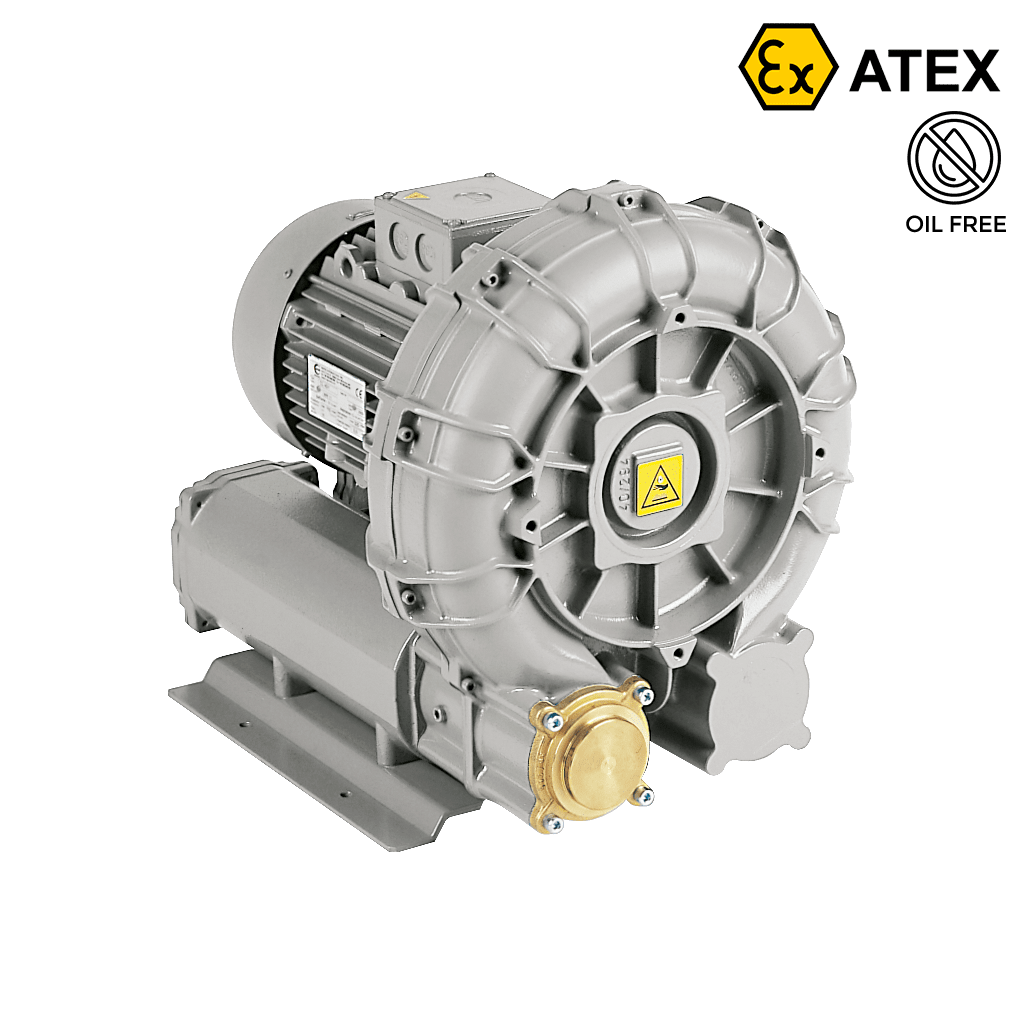

Side channel and TBT blowers (AIR/GAS)

OPERATING PRINCIPLE

The side channel blower and the TBT increase the pressure of the aspirated gas by the creation, in the peripheral toroidal channel, of a series of vortexes caused by the centrifugal thrust of the impeller. While the impeller is rotating, the vanes force the gas forward and, because of the centrifugal thrust, outwards, producing a helical motion. During this motion, the gas is recompressed repeatedly with a consequent linear pressure increase along the length of the channel.

The rotating TBT and toroidal channel are extremely innovative, born form a long research and trial. The impeller’s wing profile vanes and the central core channel allow this machine to achieve performances close to those of rotating lobe positive-displacement blowers.

CONSTRUCTION FEATURES

The MAPRO® side channel blowers to be used for extraction or compression of combustible gases, such as biological or natural gas, have been designed in order to fall within the Equipment Group II as required by the 2014/34/EU Directive, Category 2 both for the surrounding area conditions and for the internals of the machines.

Their main construction features are the following:

- casing and impellers made completely of spark proof aluminium alloy;

- casing impregnated with Loctite;

- casing halves sealed;

- shaft sealing by special double-lip seals which do not require lubrication;

- two-pole, type of protection “d”, flameproof electric motors, with specific marking Ex II 2 G, additional marking Ex-d IIB T3.

ADVANTAGES

The main advantages of using side channel machines are:

- easy installation;

- low noise level;

- no vibration;

- pulsation free gas flow;

- minimal maintenance.

Moreover, no internal lubrication is necessary and therefore the gas moving through the machine remains uncontaminated and completely oil-free.

Centrifugal Fan (AIR/GAS)

OPERATING PRINCIPLE

The MAPRO® centrifugal fans, MCF Series, are made of:

- an intake duct conveying the aspirated gas to the impeller inlet, which is coaxial to the shaft;

- a closed impeller with axial flow inlet and radial flow exit;

- a toroidal discharge volute with tangential exit.

The compression of the gas occurs through the increment of kinetic energy given to the gas by the vanes of the impeller and the subsequent conversion of the kinetic energy into static pressure in the discharge volute.

CONSTRUCTION FEATURES

The MAPRO® centrifugal fans, MCF Series, to be used for extraction or compression of combustible gases, such as biological or natural gas, have been designed in order to fall within the Equipment-Group II as defined by the 2014/34/EU Directive, Category 2 both for the surrounding area conditions and for the internals of the machine. Their main construction features are the following:

- aluminium casted casing, impeller made of spark proof aluminium alloy with caulked vanes, bearings housing made in cast iron and with aluminium casted caps, shaft in carbon steel;

- casing impregnated with Loctite;

- casing halves sealed;

- shaft sealing by a pair of special double-lip seals whose lubrication is provided by an automatic lubricator.

ADVANTAGES

The rotating parts are not in contact with the casing during rotation. There is therefore no friction during operation and thus no internal lubrication is necessary. The gas moving through the machine remains uncontaminated and completely oil-free.

The other main advantages of using the MAPRO® MCF centrifugal fans are:

- easy installation;

- low noise level;

- no vibration;

- pulsation free gas flow and no surge;

minimal maintenance.

Multistage centrifugal blowers (AIR/GAS)

OPERATING PRINCIPLE

One stage of a MAPRO® multistage centrifugal blower is generally made of:

- an intake duct conveying the gas to the impeller inlet,

which is coaxial to the shaft; - a closed impeller with axial flow inlet and radial flow exit;

- a radial diffuser, whose aim is to convert kinetic energy

into static pressure at the impeller exit; - a discharge volute.

Actually, a centrifugal blower is always used in the multistage configuration. The gas is sucked into the first stage through an inlet volute, every next single stage is linked to the former one through a return channel, and a discharge volute collects the gas from the exit of the last stage delivering it to the outlet pipe. The impellers are built with radial exit blades or backward facing blades. The radial blades allow the achievement of a higher compression ratio, whilst the impellers with backward facing blades, at fixed speed of rotation and for the same differential pressure, produce a characteristic curve with a much wider stable range.

CONSTRUCTION FEATURES

Their main construction features are the following:

- heads, intermediate sections, bearing housings and caps made of cast iron; shaft in carbon steel;

impellers made completely of spark proof aluminium alloy; - heads and intermediate sections sealed;

- shaft sealing by special double-lip seals.

The blowers are always coupled to the electric motor via belt drives and the safety drive guards

are made of spark-free material. Centrifugal blowers are designed for rotation speeds up to 6000 revolutions/min.The combination of different types of impellers, the possibility of joining several stages in series (up to 10) and the wide range of rotation speeds allow to cover, with the same machine size, a wide range of operation.

Note

Multistage centrifugal air blower and exhausters are also available for

Zone 1 and 2, 21 and 22 of the 2014/34/EU (ATEX)

ADVANTAGES

There are no parts in relative creep during operation. Since there is no friction and therefore no lubrication is necessary, the conveyed air is not polluted. Moreover, the main advantages of using MAPRO® multistage centrifugal blowers are:

- easy installation;

- low noise level;

- no vibration;

- pulsation free gas flow;

- no gas contamination;

- minimal maintenance.

Most common fields of application

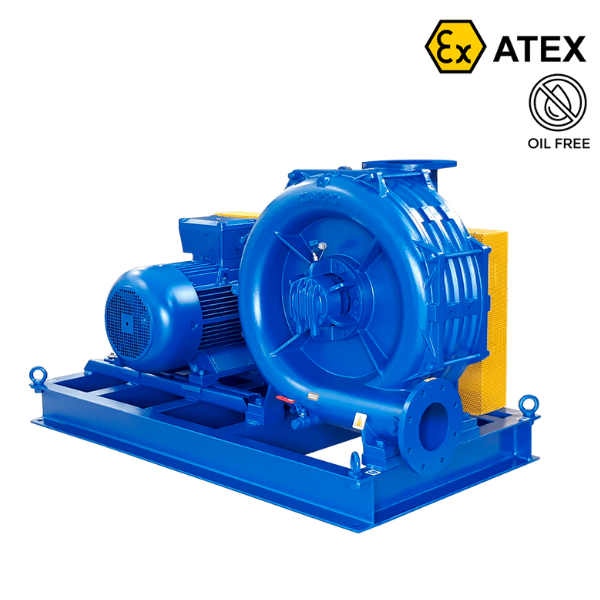

Positive Displacement Blowers

OPERATING PRINCIPLE

MAPRO® Positive Displacement machines, ML Series, consist basically of a pair of Tri-lobe rotors, mounted on parallel shafts, rotating in opposite directions inside a roperly shaped casing closed at the ends by side plates.

The two Tri-lobe rotors are synchronized by a pair of timing gears. As the rotors rotate, air is drawn into the inlet side of the casing, is moved from the inlet to the outlet side by the free volumes between rotors and stator and finally is forced out of the outlet side against the connected system pressure.

The machines, being positive displacement type, do not develop pressure within the casing but the discharge pressure depends only upon the connected system esistance.

APPLICATIONS AND ADVANTAGES

MAPRO® Positive Displacement Blowers are suitable for all those applications requiring considerably higher flow rate than that which can be achieved using side channel blowers and till 4200 m3/h, and with discharge pressure till 1000 mbar g.

The most common fields of application are:

- air injection in the oxidation tanks of the wastewater treatment plants;

- pneumatic conveying;

- air injection in saturated soils to promote biodegradation of the contaminants

(Biosparging or Bioventing).

There is no contact of the rotating parts during operation of the Blowers. There is therefore no friction between the two rotors and between the rotors and the stator and thus no internal lubrication is needed.

The gas moving through the machine remains uncontaminated and completely oil-free.

MAPRO® Positive Displacement Blowers meet the requirements of the European Directives 2006/42 (Machines), 2014/35 (Low Voltage), 2014/30 (Electromagnetic Compatibility) and of the applicable harmonized Standards.